PEPS Milling

Advanced CADCAM Software Solutions For The Manufacturing Industry

PEPS Milling is a leading CAD/CAM system that provides a practical and intuitive solution for the offline programming of 2 and 3 axis Milling machines, with support for indexable rotary axes. PEPS Milling is used in thousands of product manufacturing, precision engineering and tool making companies around the globe.

Features at a glance:

- Intuitive graphical user interface

- Extensive range of CAD interfaces; both for import and export

- Comprehensive machine and postprocessor library

- Selectable machine settings; including turret configuration, tool change position, etc.

- Standard Hole cycle functions; including drilling, tapping, boring and thread / spiral milling

- Profiling of simple or complex geometric boundaries with cutter radius compensation

- Extensive pocketing cycles; including circular, rectangular, slot and irregularly shaped profiles

- Canned cycle output for standard pocketing cycles; square, circle and slot

- User configurable and expandable Tool and Material database

- User controllable cutting depths, direction, tool overlap and finishing allowances

- Machinable fonts with user definable style, size, shear angle; inline or around an arc

- Fully customisable solid visualisation of machining sequence; including tool shape

- Sub-programming output for suitable control systems

- Calculation of cycle time for complete part

Comprehensive machine library. PEPS Milling contains a comprehensive library of milling machines from a large number of leading Machine Tool manufacturers; including Acramatic, Deckel, Fadal, Fagor, Fanuc, Haas, Heidenhein, Hitachi-Seiki, Hurco, GE, Maho/Philips, Matsuura, Mori-Seiki, Num, Protrak, Siemens and Yasnac.

Full range of drilling cycles. Centre drilling, drilling, tapping, reaming, boring, helical milling, thread milling and mill drill cycles give the user a choice of operations to cover any combination of hole type. Selection of diameters and depths straight from the model makes it easy to enter drilling parameters and eliminates the possibility of errors. Optimisation of the toolpaths ensures the shortest distance for the tool travel, saving machining time on complex hole patterns.

2D profile machining and face machining operations. The profiling operations give a choice of machining direction, circular or direct approach, and the ability to cut down to a depth with a sequence of profiling moves all in one command. Cutter radius compensation capability provides practical CNC code for use on the shop floor. Where the cutter cannot machine tight internal radii, the system will automatically provide the correct information to enable re-machining with a smaller tool. Spiral or zigzag face milling operations provide a choice of methods to clean up faces offering maximum flexibility.

2.5D toolpaths from simple 3D forms. Within PEPS Milling it is possible to generate 2.5D toolpaths for simple standard 3D forms; such as cylinder, plane, sphere or ruled surface, without the need to have PEPS 3D Surface machining module or indeed to create a 3D model. Standard machining routines are included for machining blends and chamfers onto sharp edges.

Program user definable macros. PEPS Milling has the functionality to create user-defined macros which can automate the most common and preferred methods of machining features. By setting depths of cut, tools, sequences of operation and cutting conditions, your parameters will be used automatically every time. Encouraging the use of consistent working methods will reduce the time spent on deciding the best machining method and make sure that the quality of finish meets the requirements of each job.

Open and closed pocket machining. PEPS Milling allows pocketing operations with multiple islands with multiple depths and the ability to define draft angles and top and base radii for the pocket and on the islands, or to apply a freeform shape to the pocket or island to define its wall. For open sided pockets the user can identify the open faces and the cutter will then automatically move across the open edge to remove any residual material.

Comprehensive tool and material database. PEPS Milling has a fully integrated tool management database. Tools and tool holders are stored with all the relevant data associated to material types and cutting conditions. Default programming styles can be set up so that accurate information is automatically returned to the programmer; such as feed and speed information. The tool database can be intuitively interrogated using standard searching, ordering, grouping and filtering functionality.

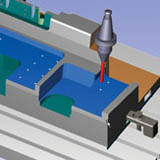

Toolpath verification and simulation. Once programmed, the job can be simulated in realistic rendered solids. PEPS Milling automatically checks the tool and the holder against the model and fixturing and provides a warning when there is going to be a collision, both graphically and via on-screen warning messages. Graphical verification of the completed toolpaths shows the sequence of operations and the surface finish. The cut part can be compared with the original model, to ensure that the part has been completely finished. Using visualisation helps to make sure the job is made right first time.

Configurable postprocessors. An extensive library of advanced postprocessors is available to suit most machine tools and all postprocessors are fully configurable to suit individual requirements; they aren’t just limited to the use of generic G and M codes. Canned cycles for drilling, subroutines to reduce program length, circular interpolation, cutter radius and tool length compensation all combine to produce reliable NC code which is easy to use on the shop floor.